Ball Valves

Ball valve is mainly used to cut off, distribute and change the direction of medium flow in pipeline. V shaped ball valve opening also has a good flow adjustment function. Ball valve only needs to be operated with a rotation of 90 degrees and a small turning torque to close tightly. The completely equal valve body cavity provides a direct flow channel with little resistance for the medium.

Ball Valve has a simple structure and good sealing performance. It can configure smaller nominal diameter, lightweight, low material consumption, small installation size, small driving torque, simple operation, easy to realize quick opening and closing, and easy operation within a certain nominal passage range and maintenance. The ball valve is suitable for general working media such as water, solvents, acids and natural gas, but also for media with severe working conditions, such as oxygen, hydrogen peroxide, methane and ethylene.

Check Valves

Check valves are also called non return valve, reflux valve, retention valve or one-way valve. This type of industrial valve is automatically opened and closed by the force generated by the flow of the medium itself in the pipeline, which can categorize as an automatic valve. Check valves are used in pipeline systems, their main functions are to prevent backflow of the medium, to prevent the pump and its drive motor from reversing, and to backflow of the medium from container. The check valve can also be used to replenish the auxiliary system where the pressure may rise above the pressure of the main system.

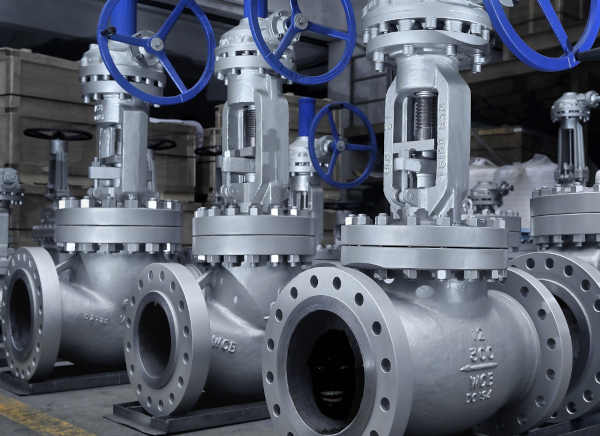

Gate Valves

Gate valve refers to a valve whose closing member (gate) moves in the vertical direction of the center line of the passage, mainly constructed by valve body, bonnet, stem gate, sealing packing, handwheel/gearbox and other components. Normally the two ends of the valve are connected to the pipeline with flange using studs and nuts.

Globe Valves

The Globe valve is used to cut off the flow of the medium and is suitable for occasions that need to be throttled frequently. The most commonly used is in chemical production.

The valve disc and the valve seat is the sealing parts of the globe valve. In order to close the valve tightly, the matching surface of the valve disc and the valve seat should be grinding, and the corrosion-resistant and wear-resistant materials such as Stellite 6 and stainless steel can also be welded on the sealing surface. The valve disc and the valve stem of the globe valve are designed flexible connection to facilitate the valve disc and the valve stem fitting.

Butterfly Valves

Moto Valve is an industrial butterfly valve manufacturer selling four types of butterfly valves. Our valve factory produces high-performance metal seals and butterfly valves for high-pressure industrial applications.

Moto Valve is also a provider of two types of eccentric butterfly valves, the double and triple eccentric. The double eccentric form is mostly used in power generation and petrochemical applications, while the triple eccentric is used in more demanding industrial applications.

The butterfly valve comes from the family of the quarter-turn valve. It is named for its butterfly disk, which serves as a gate to open or shut the valve. The butterfly valve looks identical to the ball valve. The benefits of Moto Valve butterfly valves include reliability, simple working, and fewer maintenance needs.