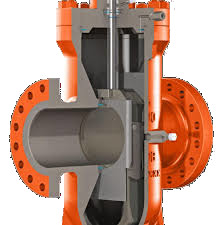

API 6D Expanding Gate Valve

- Product Description

- Design Features

- Product range

Expanding Gate Valves are manufactured with a full bore port and with 2-piece (gate + segment) obturator designed for a positive, bubble tight shut off upstream and downstream under both low and high differential pressure. Double block and bleed capability and high robustness are standard feature of this seat design.

The smooth, continuous bore minimizes turbulence within the valve and when in the open position it produces a pressure drop equivalent to a portion of pipe of same length and diameter. The seat faces are outside the flow stream and therefore protected from the erosive action of the flow.

Pigs and scrapers can be run through the valve without damage.

Design standard as per: API 6D、ASME B16.34、GB/T 19672

its performances as small operation torque, better sealing, lower noise during operation, safety and reliable operation;

The valve disc and valve seat seal are repeatedly treated by special processes, and protected by multiple seals, and featured with anti-corrosion, penetration-proof, anti-abrasion and long service life;

Valve seat is designed with hard-soft double seal, having reliable tightness;

With a full bore design, both the coefficient of flow resistance and the pressure loss are very small;

When the valve is fully opened, medium erosion occurring to its sealing face is smaller than that of other valves;

The through conduit gate valve with diversion holes installed on a pipeline can also be cleaned by a pipe cleaner directly;

No space restriction on valve installation, that is, both parallel and perpendicular installations are allowed.

Body material:

- carbon steel,

- stainless steel.

Sizes

- From 2” to 60″

Pressure Ratings

- From 150# to 2500#

Connection Types

- RF (Raised Face)

- RTJ (Ring-Type Joint)

- M (Male)

- F (Female)

- BW (Butt Weld)

Temperature range

- -196 ~ +907℃

Operation

- handwheel,

- gear box,

- electric / pneumatic actuator,

- electro-hydraulic actuator